Blog

Traffic jams on the PROFINET

Introduction: When PROFINET was first released, almost all the nodes communicated at 100 Mbps. You had the odd device that communicated at 10 Mbps, but that was non-PROFINET and was not a big deal. In the last few years, things have changed. We now have 1,000 Mbps...

Using PROFIBUS DP waveforms to troubleshoot network issues

Looking at the PROFIBUS DP waveforms and signal levels are key to determining if there is a problem and identifying that problem. In the last update of both our PROFIBUS Troubleshooting and Maintenance course and our Certified PROFIBUS Network Engineering course, JCOM...

Modbus is DEAD! Long live Modbus!

Modbus is the Grand-daddy of industrial protocols. It has been around since the mid-70s. One would think it had gone the way of the Eight-track tape by now. I have heard, 'Oh Modbus, it is dead - isn't it?' Well, No, it is not. As I have travelled around doing field...

ChatGPT, PROFIBUS and SNAP

There has been a lot of talk about ChatGPT. My colleague Cambel Lai has been playing with it, and it is certainly impressive technology. However, as others have noted, it should be used cautiously. This is especially true when applied to industrial communications. We...

The convergence of OT and IT from a Diagnostics Point of View

Chapter 1 Introduction to Diagnostics in Operational Technology Operational Technology (OT) deals with all the technology used to control a factory or process plant. In the last 30 years, it has seen three significant changes. The first was the introduction of...

The benefits of digital deployment of HART Instruments

Highway Addressable Remote Transducer (HART) has had a long history and is used extensively in process automation. In the early days of HART, the protocol was mainly used to set up instruments in a point-to-point manner using a HART Modem. Now, these HART instruments...

The HP-25 Cable tester to the Rescue!

My PROFIBUS troubleshooting tool of choice is ProfiTrace by PROCENTEC – an excellent tool. In my toolbox, I also have a cable tester called the HP-25 by HI-PORT CONTROLS in the UK. If I am working on a new segment, I will take it out and use it. However, up until now,...

Maintaining a PROFIBUS network with COMBRICKS and ProfiHubs – a Maintenance person’s dream come true!

Life as a maintenance person can be very difficult at times. They are presented with mysteries on a daily bases. One of my favorites is when there is a temporary PROFIBUS issue – you are called down to the machine but by the time you get there, everything is working...

Why use an EtherTAP & Osiris to Troubleshoot PROFINET networks

Recently, PROCENTEC released an aggregated TAP (Test Access Point) called EtherTAP for use with either Wireshark or Osiris running on Atlas or Mercury. I loved the device! It gave me the sense that I could finally see what was going on. Why did I feel this way? Before...

Report from the 2019 PROFIBUS PROFINET International Meeting in Innsbruck Austria

Being a PROFIBUS PROFINET International (PI) Competence Center (PICC) and PI Training Center (PITC) for both PROFIBUS and PROFINET means that we need to stay current on what is happening. To do this, PI has a meeting of PICC and PITC once a year, and this year it was...

Newsletter and Book Download

JCOM Automation Inc. produces a newsletter a few times a year updating our customers on upcoming training opportunities, interesting applications and new products. Please sign up here, and you can download a free copy of ‘Catching the Process Fieldbus – An Introduction to PROFIBUS and PROFINET,’ as our thank you.

The book is co-authored by our principal engineer and owner, James Powell.

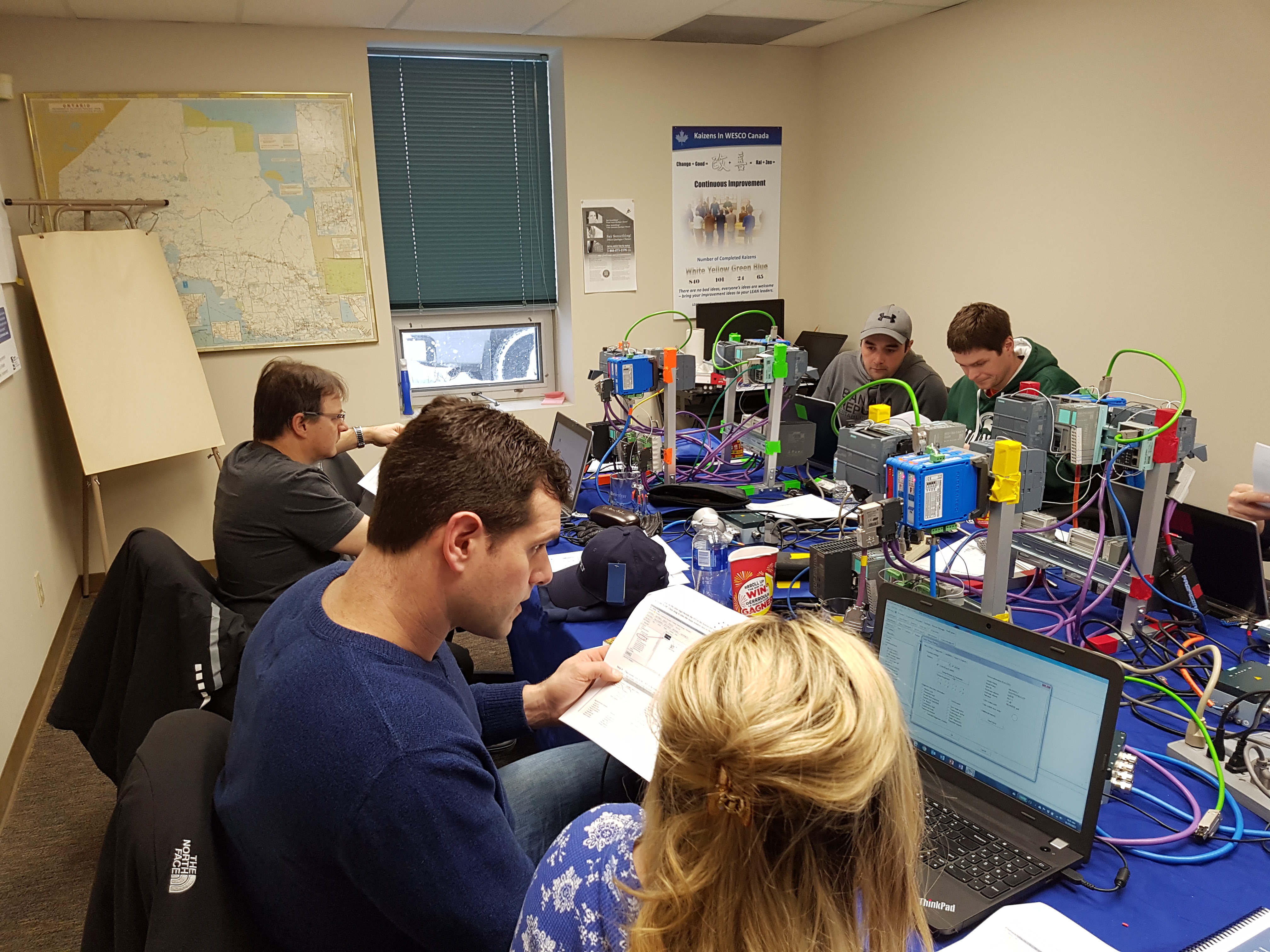

We offer training courses

JCOM Automation Inc. offers high-quality, hands-on training. Our courses have a lot of labs, and we have all the latest equipment, including state of the art diagnostic equipment. We offer training on; PROFIBUS, PROFINET, EtherNet/IP, Modbus TCP, Modbus RTU, and HART. For a quote on a course, please contact us directly.

We are a certified training center for PROFIBUS PROFINET International for both PROFIBUS and PROFINET, which guarantees high-quality training.